Great content. The most valuable was the basic laws and physics around hydraulics. This is important and essential to help with troubleshooting. A very effective teaching style.Craig M., Tolko

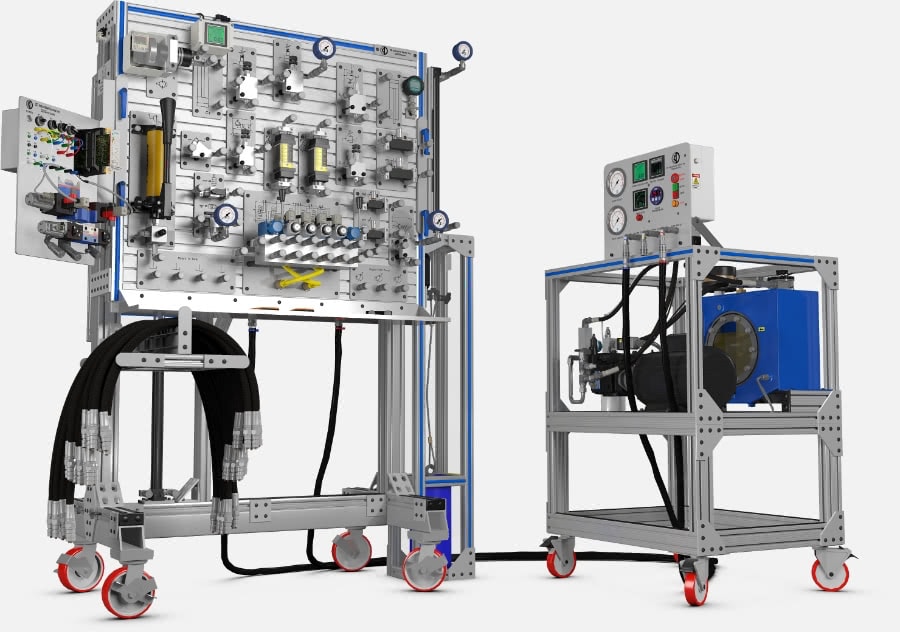

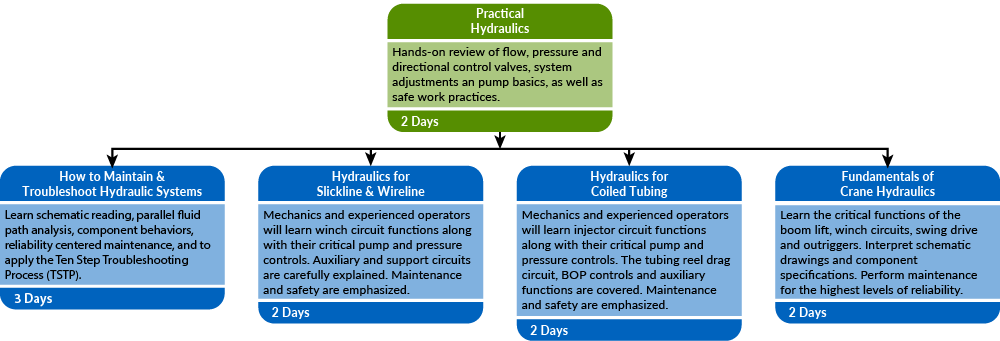

Fluid Power Basics

Objective: Explain fundamental fluid power principles

Activity: Calculate force, pressure and surface area

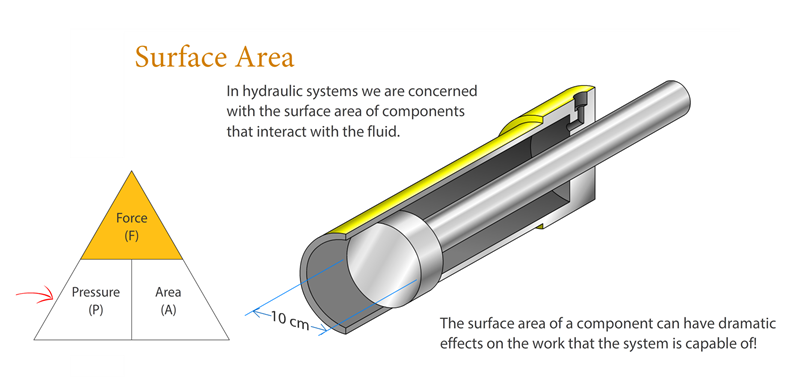

The FPA triangle helps students remember the relationship between force, pressure and area using a simple image.

Very informative and exciting. Great use of visual with the animations. Completely worthwhile to anyone who works with hydraulicsTerry D., Rangerboard

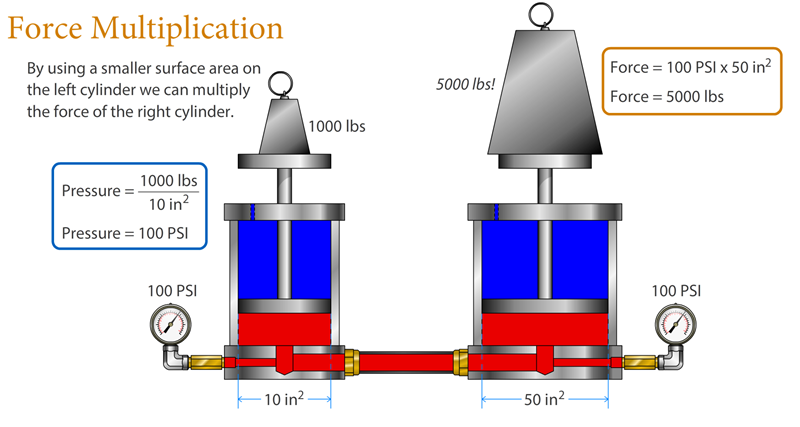

Fluid Power Math

Objective: Describe design principles

Activity: Calculate force multiplication in hydraulic systems

How can low pressure work with large forces? You'll find out!

The demonstrations and practical work were great in helping to visually understand everything that goes on.Dustin, Mechanic, Teck Coal

Pump Basics

Objective: Identify types and characteristics of pumps

Activity: Correctly connect a pump to a fluid source and circuit

Fixed and variable displacement pumps have very different characteristics. Recognizing which kind of pump you are working with is vital in understanding system behavior.

I learned the ability to verify pump settings on hydraulic systems.Drake A, Sanjel

Pressure Valves

Objective: Differentiate between various types of pressure valves

Activity: Connect and correctly adjust pressure valves

Recognize pressure valves by sight & read the symbols like a pro.

This course is perfect for people who have a basic understanding of hydraulic systems and need hands-on training.Jeff D., Zedi

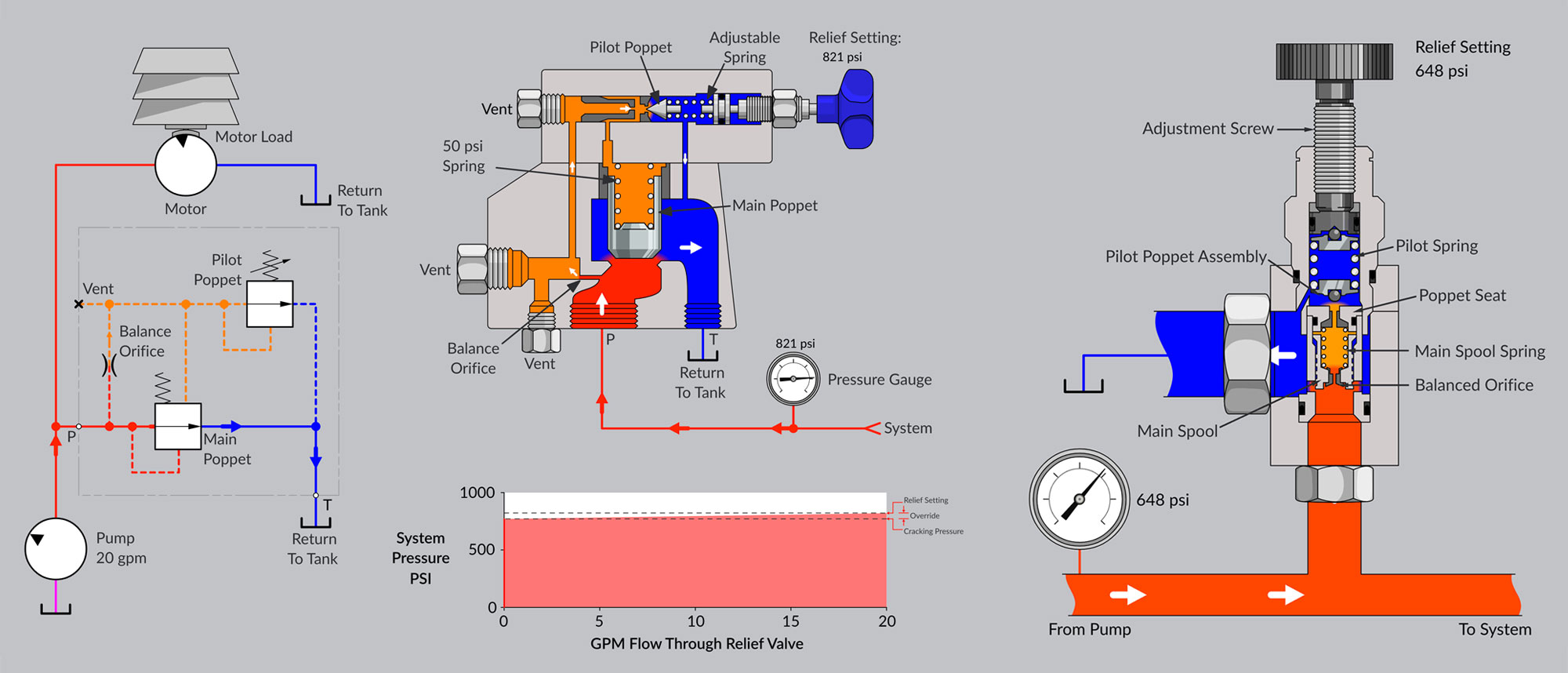

Pressure Relief Valves

Objective: Explain single acting and balanced relief valves

Activity: Measure cracking pressure versus full-flow, setting pressure

Detect and compensate for pressure override in any pressure valve

Animated schematics make valves a lot easier to follow. Great teaching techniques.Brad, Mechanic, Syncrude

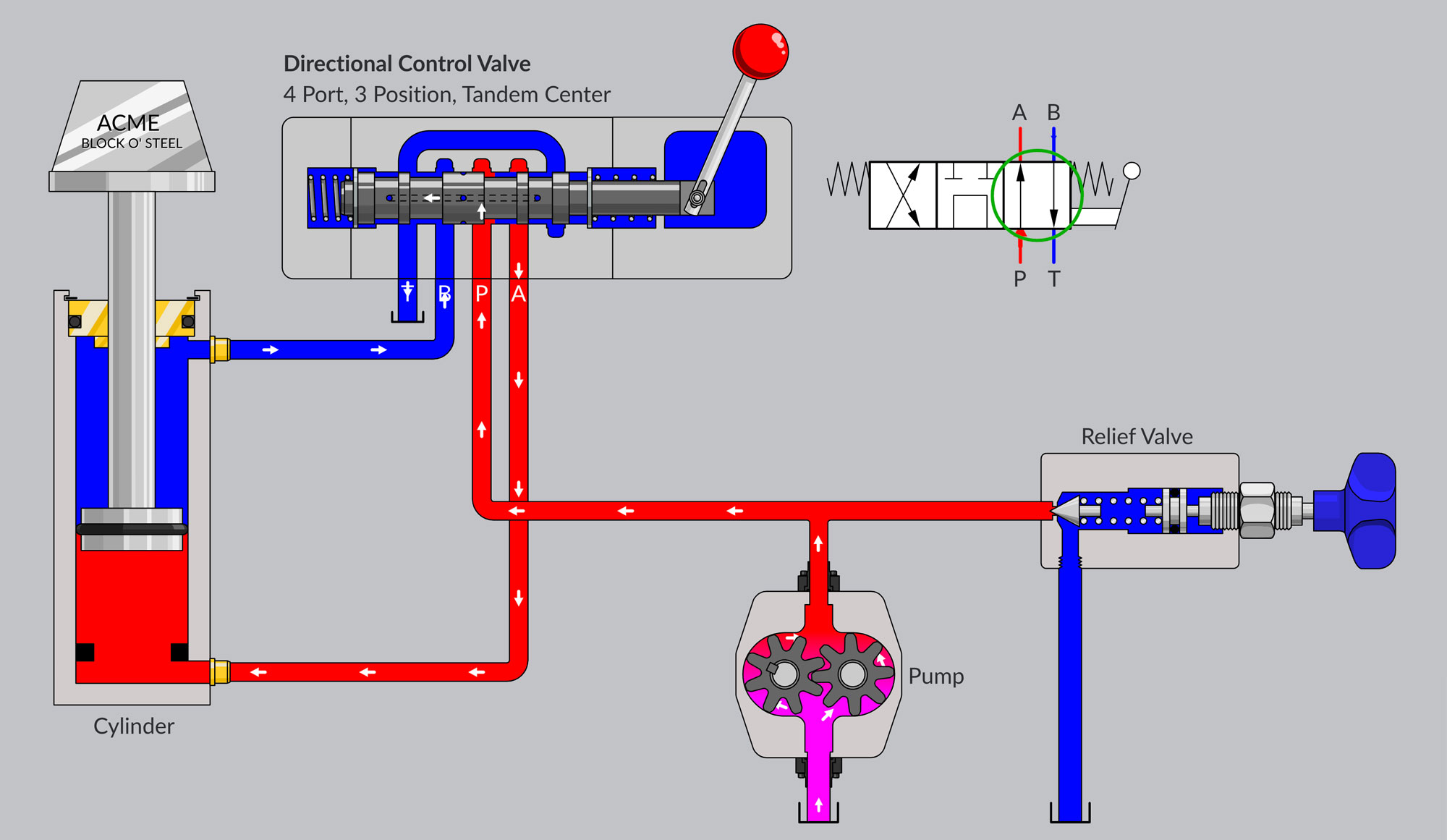

Directional Valves

Objective: Explain directional valve types and circuit configurations

Activity: Connect and configure open, closed, tandem and float center directional valves

Know your 2, 3 and 4 port directional valves

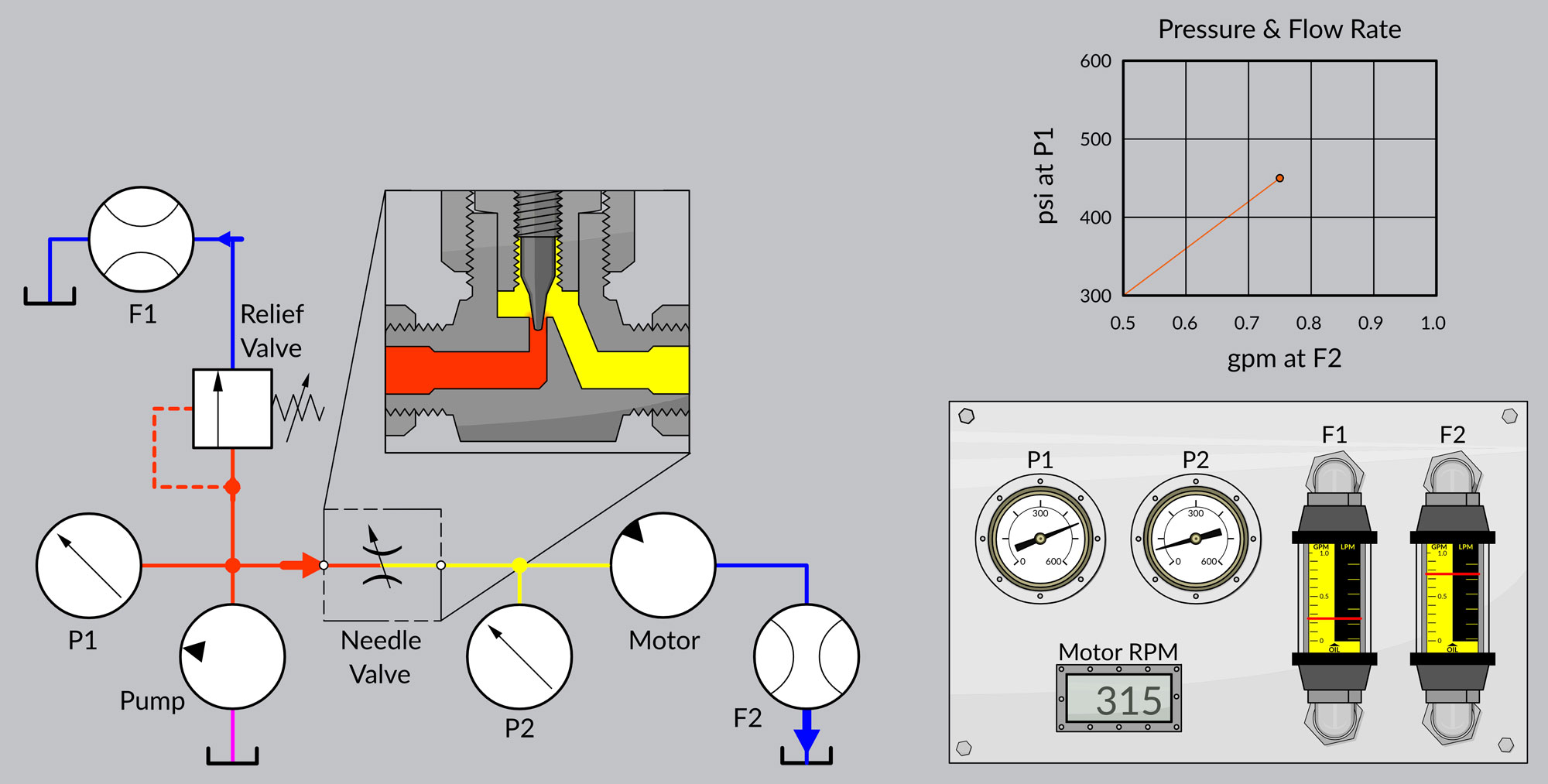

Flow Control Valves

Objective: Predict the effect of flow control adjustments on actuators and pressure values

Activity: Connect flow controls into typical configurations for hydraulic circuits

Achieve clarity on meter-in and meter-out flow control modes

Cylinders and Motors

Objective: Predict motion and pressure responses at actuators

Activity: Connect and load a cylinder and motor and read pressures

Know your actuator displacement, speeds and pressures

It's a really good course. It will help you read and understand schematics much better.Dana M., Shell

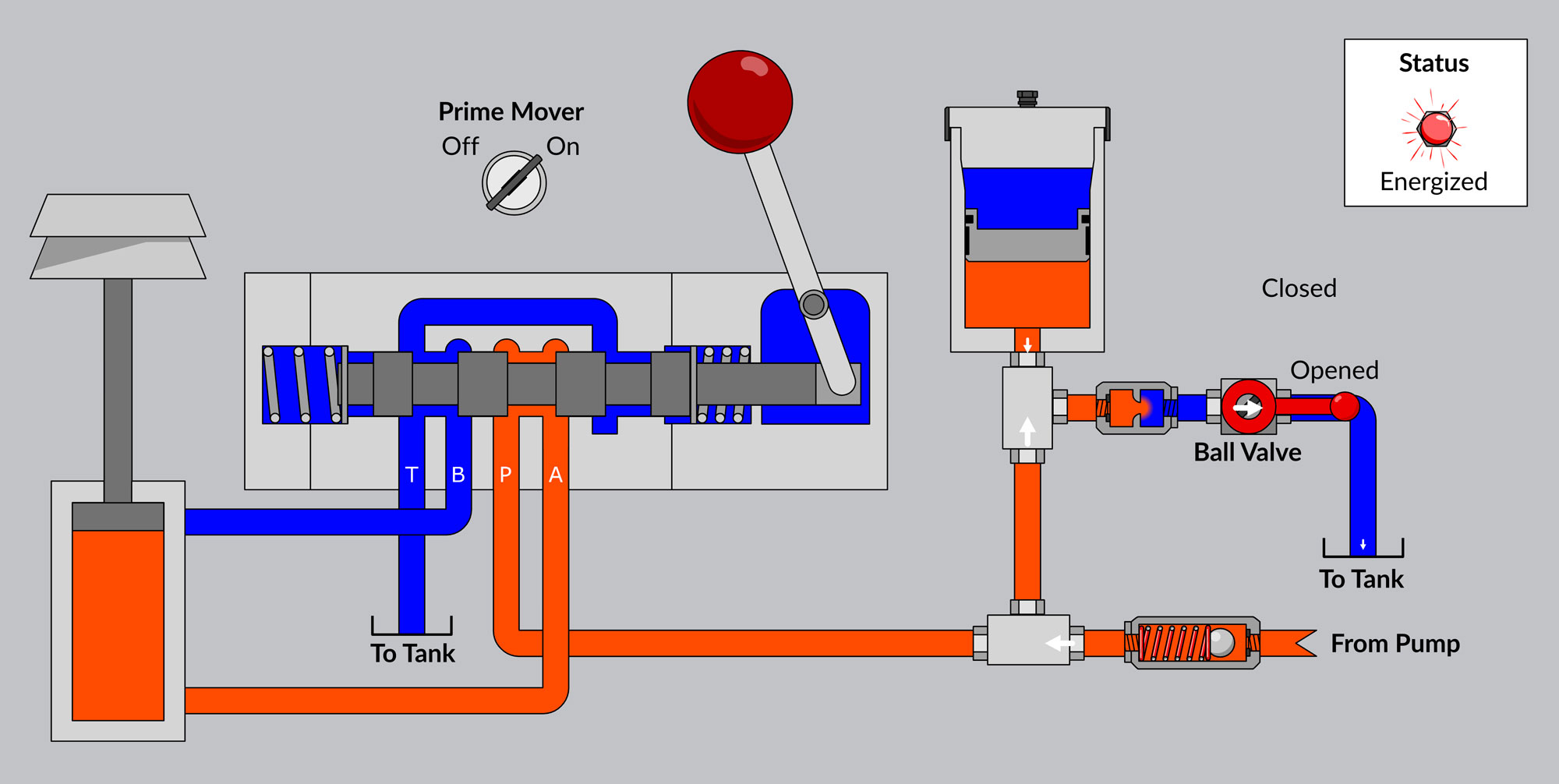

Safety

Objective: List hydraulic system hazards and proper work precautions

Activity: Bleed down pressures and verify a zero energy state

Develop safe work habits and procedures around hydraulics

I now realize the hazards of working with hydraulics, that I didn't know before.Ines H., Mechanic, Pioneer Natural Resources