System Parameters

Objective: Review hydraulic principles and misconceptions that affect troubleshooters

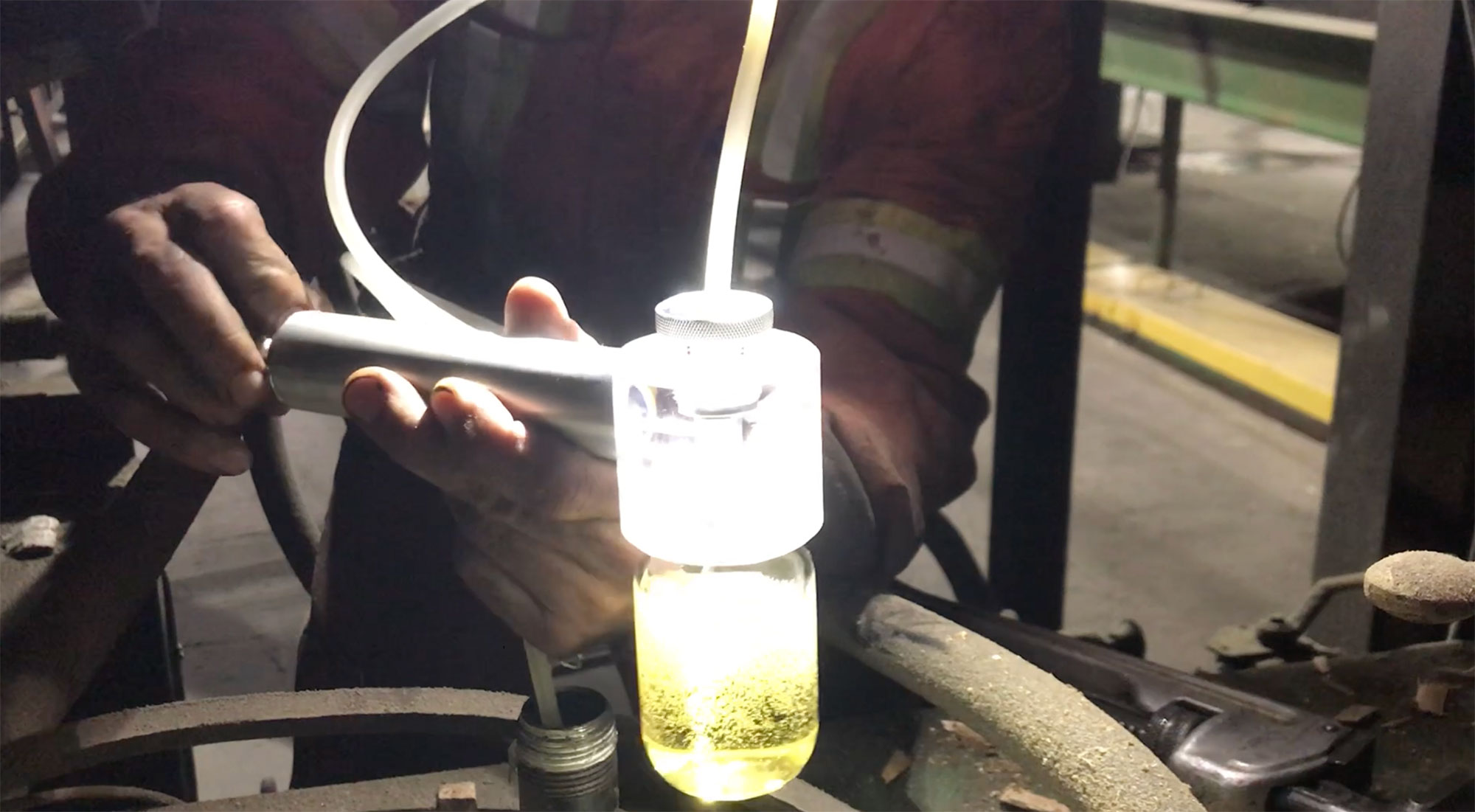

Activity: Conduct a load (volumetric) test on a piston pump

Avoid troubleshooting guesswork by knowing the condition & properties of the fluid source - the pump!

This is the next generation of training with fantastic content. No one gets bored when learning. Obviously, these guys know their stuff. What's great is how interactive they are. Best course I've ever taken.Gary B., Mechanic, Syncrude

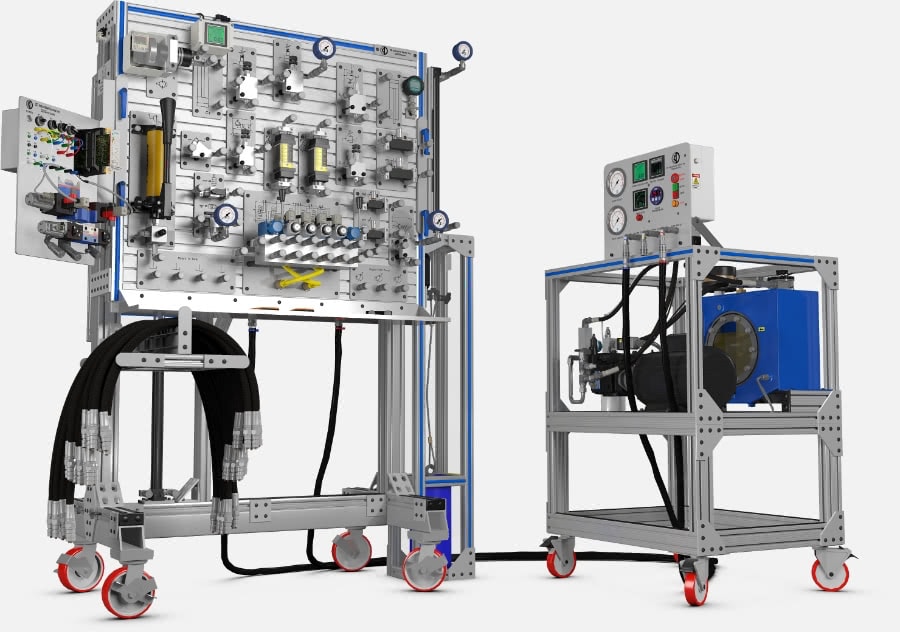

Systems Design

Objective: Analyze complex circuit designs

Activity: Design and connect circuits on our training panel, to solve basic hydraulics problems

Learn to recognize groups of valves and designs within larger systems!

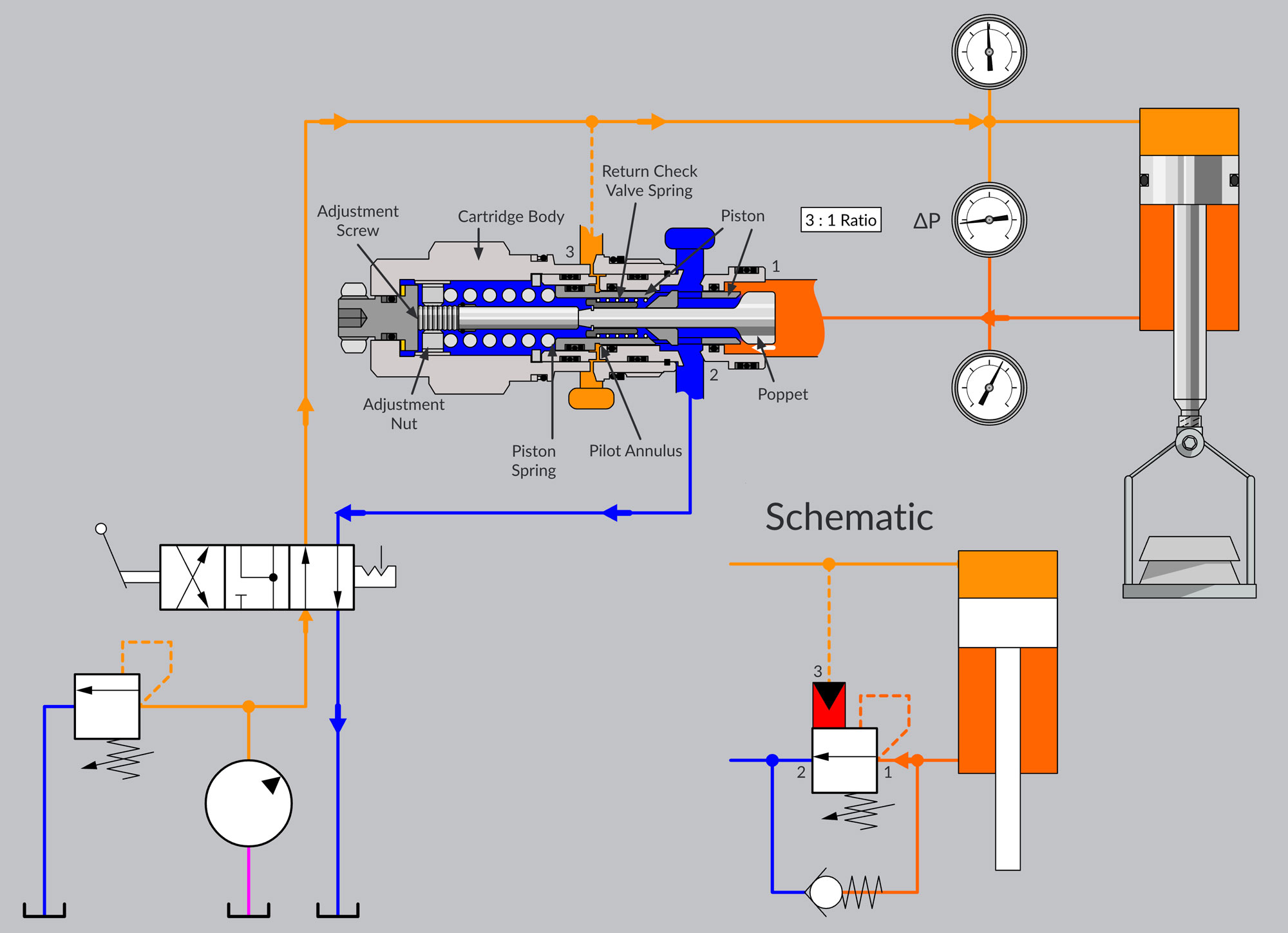

Safe Valve Adjustments

Objective: Set pressure valves using the correct, safe method

Activity: Adjust a counterbalance valve, safely, in simulation and on our training panel

A one quarter turn of a pressure valve adjustment can increase pressure by 500 psi!

I learned how to methodically check a system fault. A very intense course. Fantastic!Ian M., Mechanic, City of Lethbridge

Preventative Maintenance

Objective: Describe preventative maintenance procedures

Activity: Identify maintenance tasks and frequencies for given systems

Find out what it takes to get long life from your systems!

Very well laid out course with in-depth hydraulics discussion. (Trainer has) high knowledge base for complicated hydraulic systems. I would highly recommend this course to anybody wishing to learn more hydraulics.Terry M., Millwright, Johns Manville

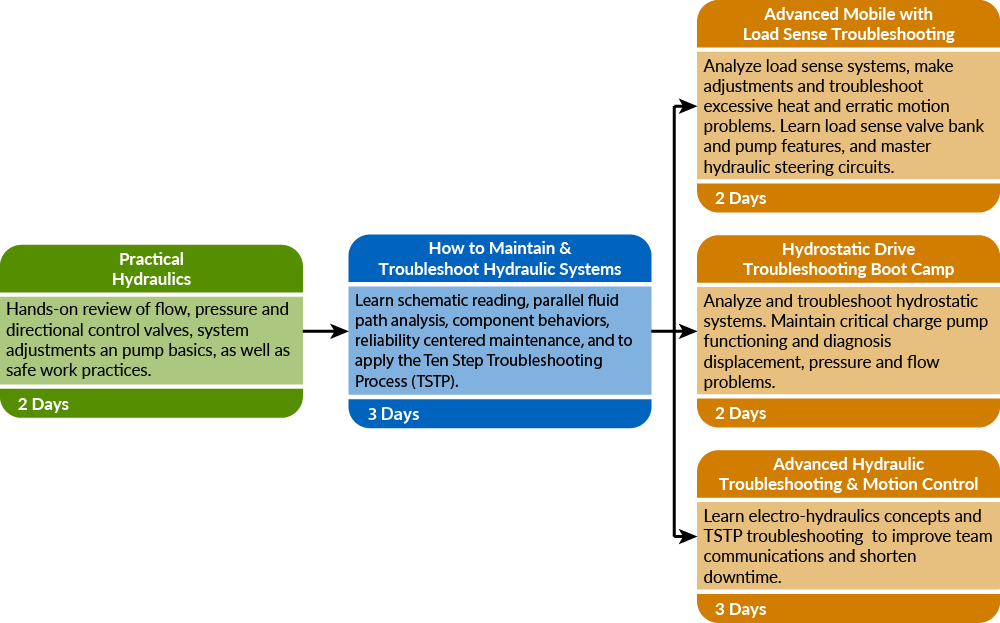

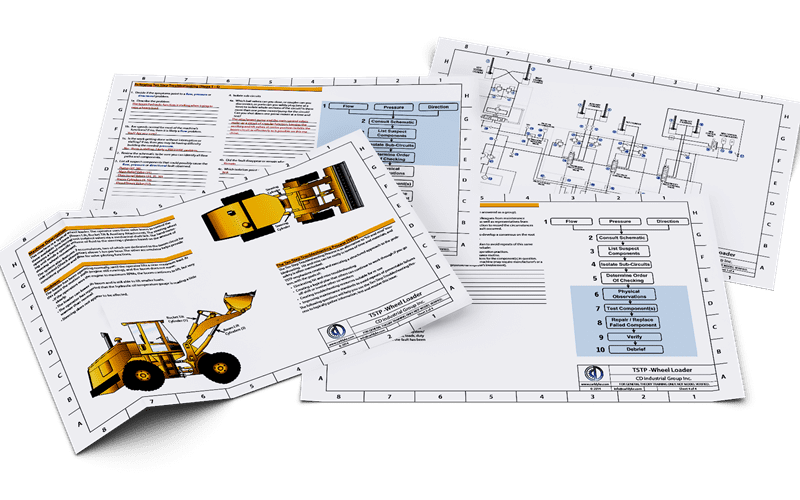

System Troubleshooting - Mobile

Objective: List the steps in logical troubleshooting

Activity: System troubleshooting simulation exercise

Learn the ten steps to logical and organized troubleshooting!

One of the best put together courses - a must take!Don C., Ring Container

System Troubleshooting - Plant

Objective: List the steps in logical troubleshooting

Activity: System troubleshooting simulation exercise

Learn the ten steps to logical and organized troubleshooting!

The animations definitely improve understanding of the function of a system and the exercises made us think about the material.Lee H. Teck Metals

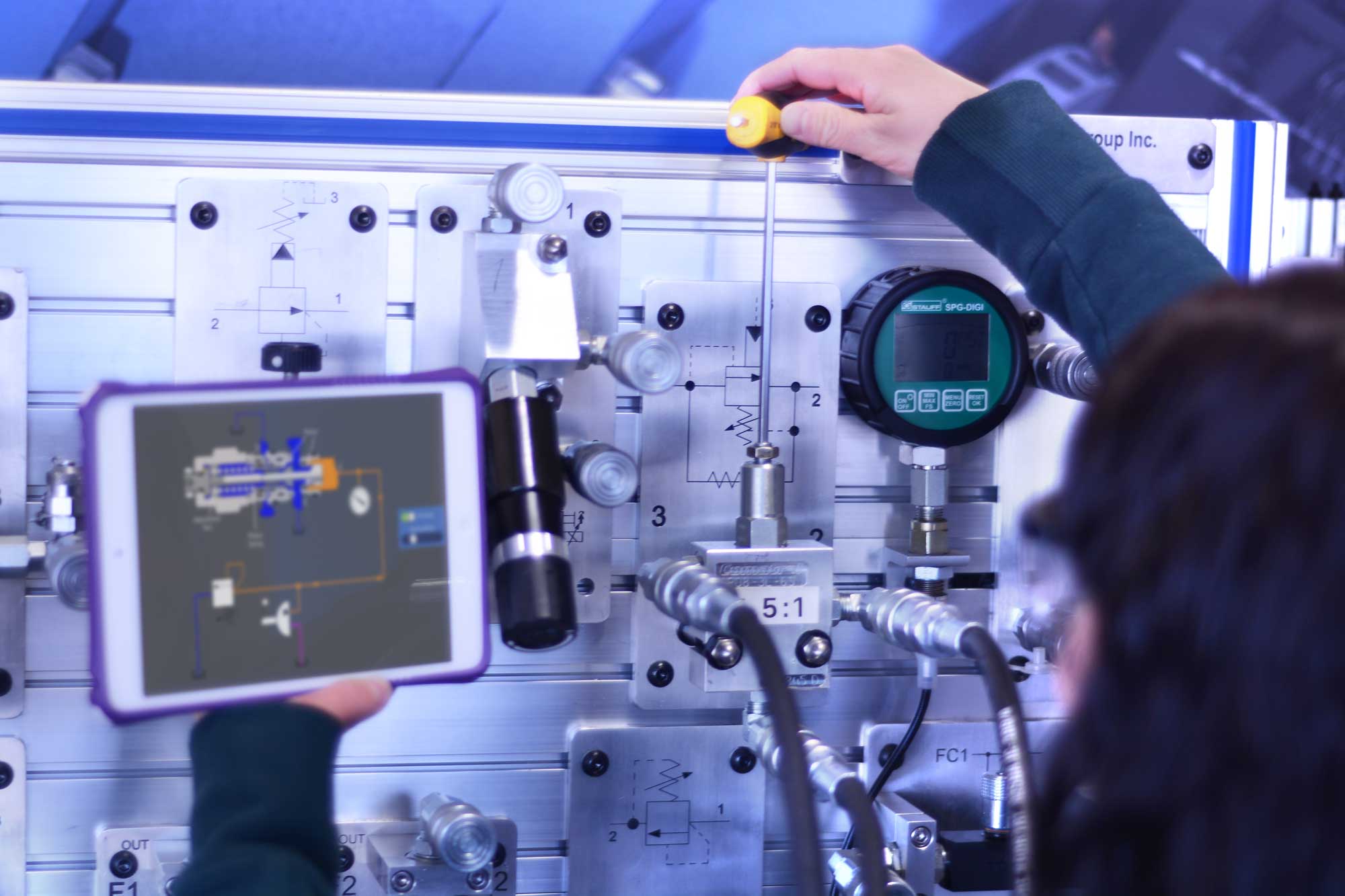

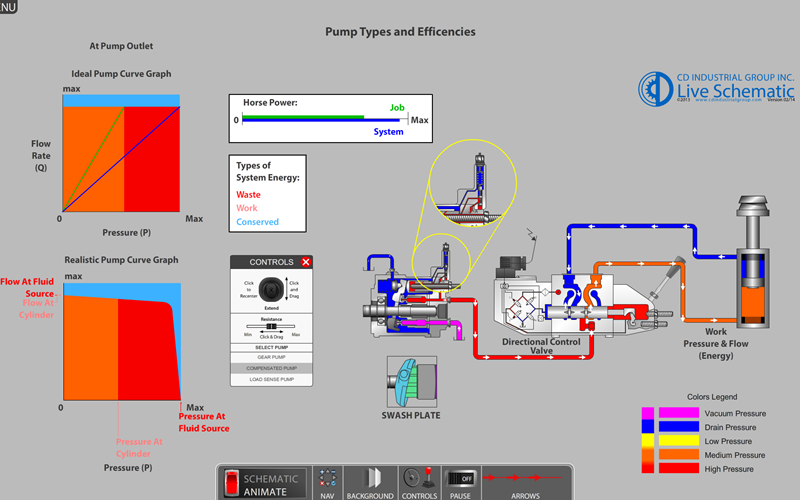

Hydraulic Pumps

Objective: Compare and explain the principles of various hydraulic pumps

Activity: Work with a simulation and with actual pumps on our training panel

Learn to correctly adjust a pump compensator!

I learned the meaning of "clean", the importance of accurate schematics, and the understanding of valves. I'm going to keep the binder with me as it very understandable.Joe O., Graymont Western Canada Inc.

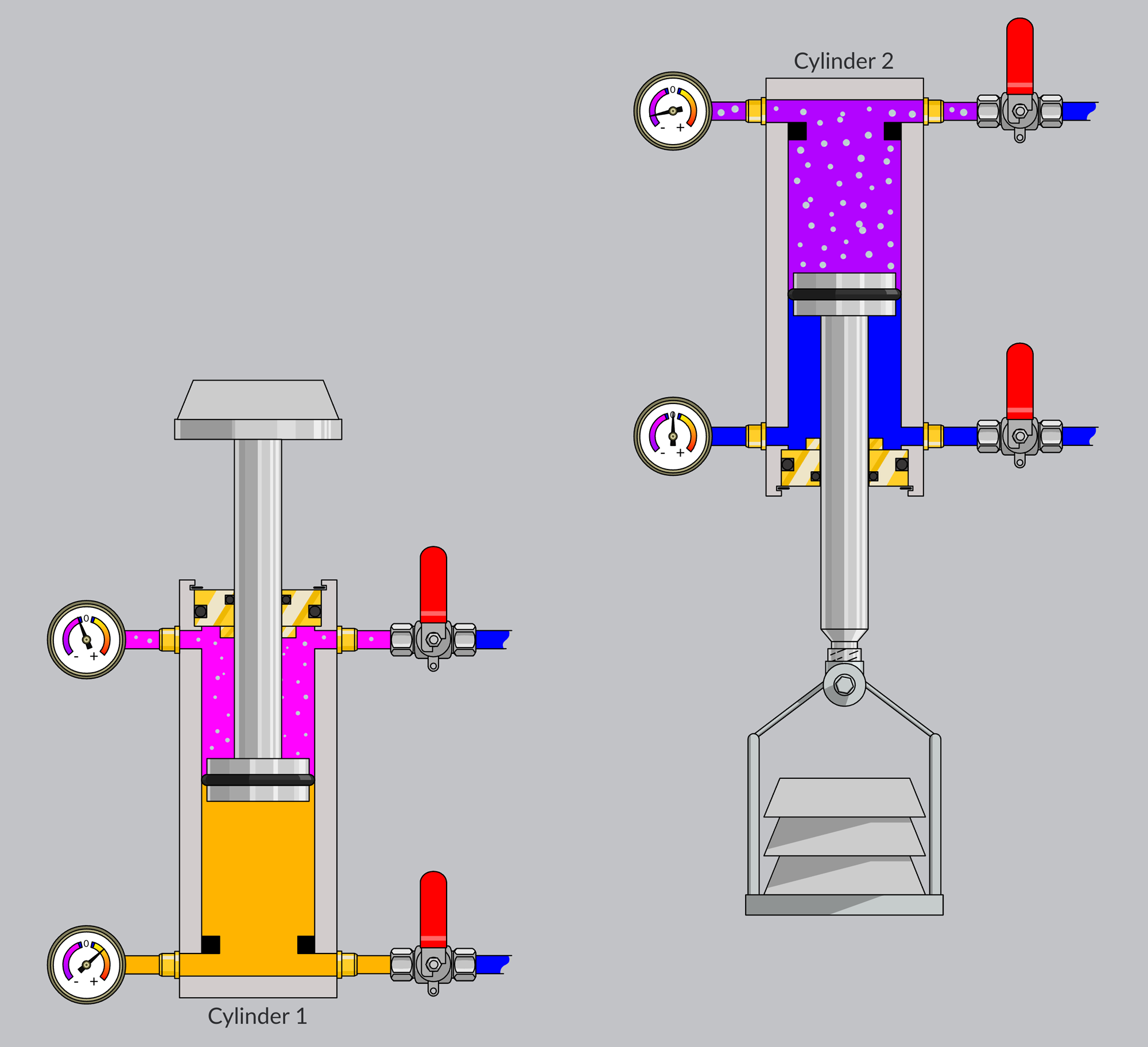

Actuators

Objective: List procedures to diagnose common problems in cylinders and motors

Activity: Work with an internal cylinder leakage simulation and with our cylinder bypass panel

Learn cylinder drift myths, and steps to keep actuator strain to a minimum!

I liked the graphic animation of hydraulic systems, makes it easier to visualize.Thomas G., BC Rapid Transit

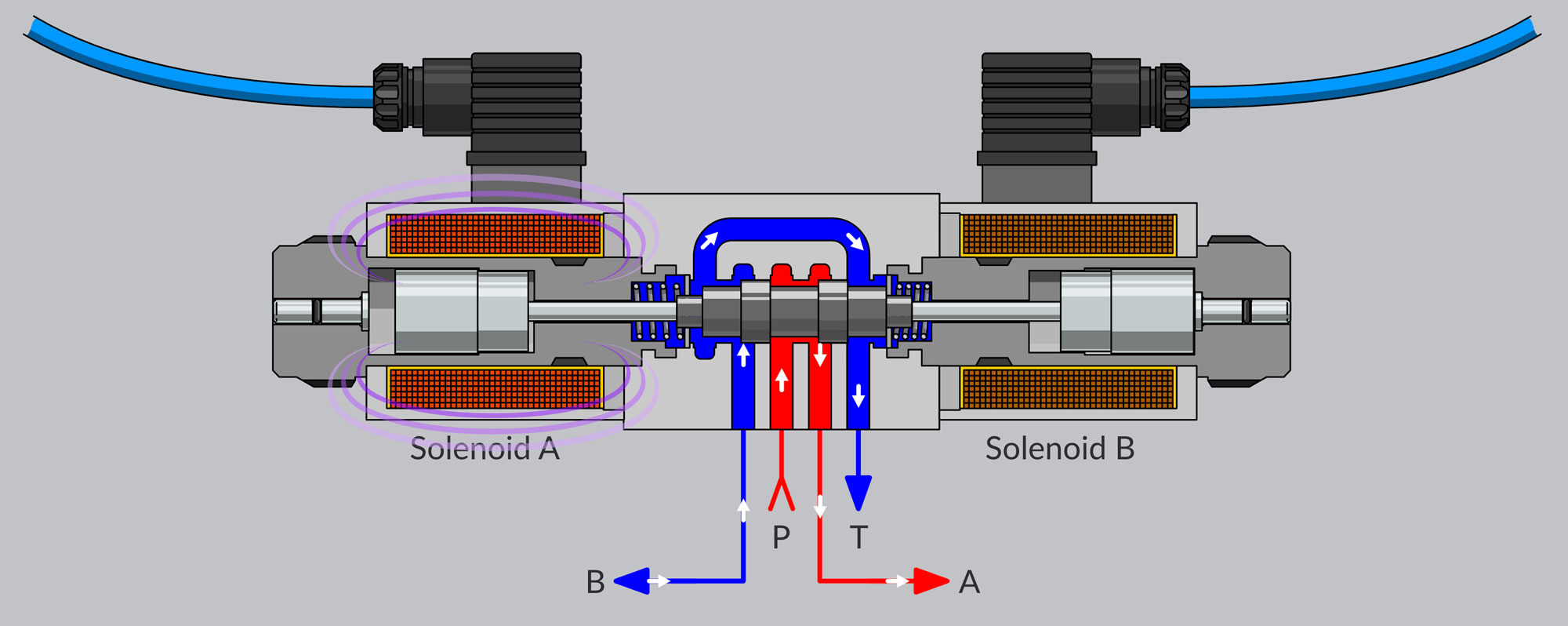

Valves

Objective: Identify valve designs and diagnose common problems.

Activity: Solenoid tests & valve disassembly, inspection and reassembly

Learn to make logical checks to determine a valve problem!

Animations are excellent. I learned a lot and want to hold a version of this course on our terminal. I believe this course will pay for itself right away!Joel W., DP World