The interactive, animated material is exceptional. It clearly illustrates CT functions and operation, and allows a visual interpretation of adjustments made to the system.Joseph A., Baker Hughes

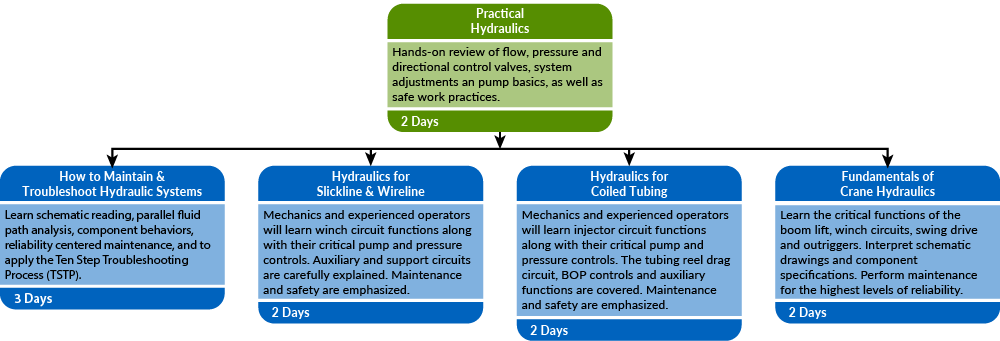

Power Unit - CT Circuit Pumps

Objective: Identify the hydraulic pumps and their circuit functions

Activity: Locate the position of each pump on the tractor or skid based power unit

Sort out which power unit pump provides flow for particular coiled tubing functions

I really enjoyed learning about the P11P pump and also diagnostic techniques. The instructor explained everything in-depth and adapted well to operator questions.Josh P., Canyon Technical

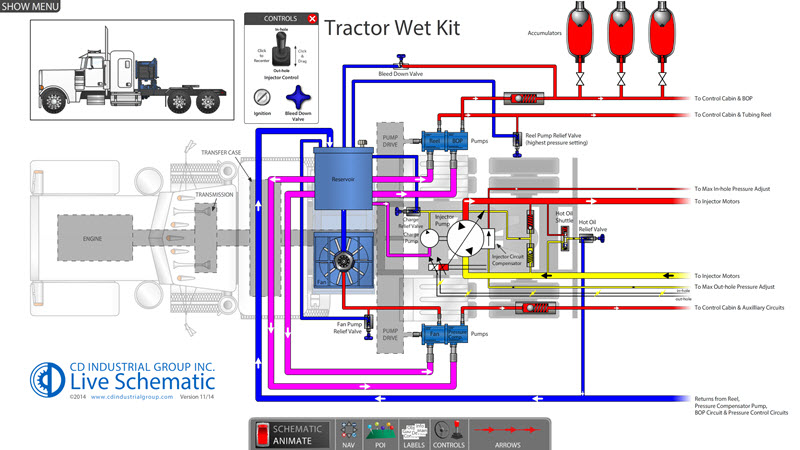

Injector Circuit - Brake Functions

Objective: Identify critical fail-safe brake and functions

Activity: Interpret injector schematics and valve components

Maintain drain lines and quick coupler connections for safe, reliable performance

Content is very useful and is very in-depth and specific to circuits on our units. Very useful for operations and maintenance.Dave F., Calfrac

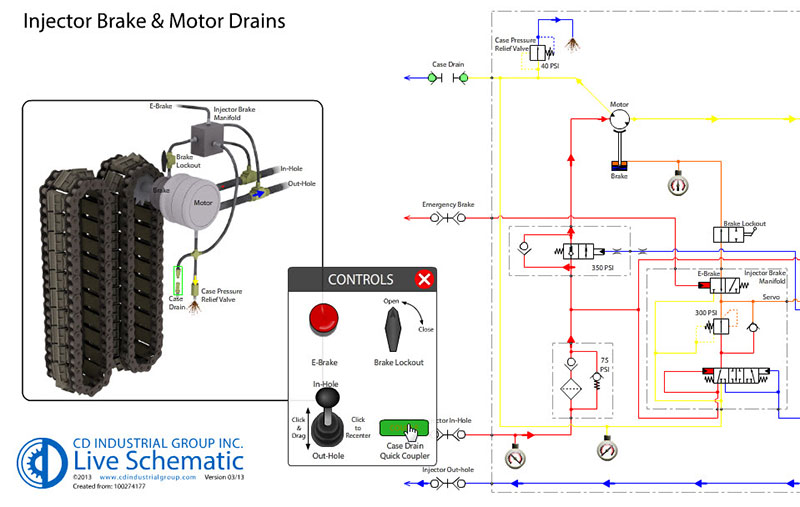

Injector Circuit - Motion Control Functions

Objective: Describe the correct settings and functions for counterbalance valves

Activity: Explain expected motion control for potential runaways: "pipe-heavy" and "pipe-light"

How much fluid contamination does it take to make a counterbalance valve unreliable?

The course is very well set up with simulations and hands-on activities. Makes it easy to understand and apply to real life.Kalen F., Precision Well Servicing

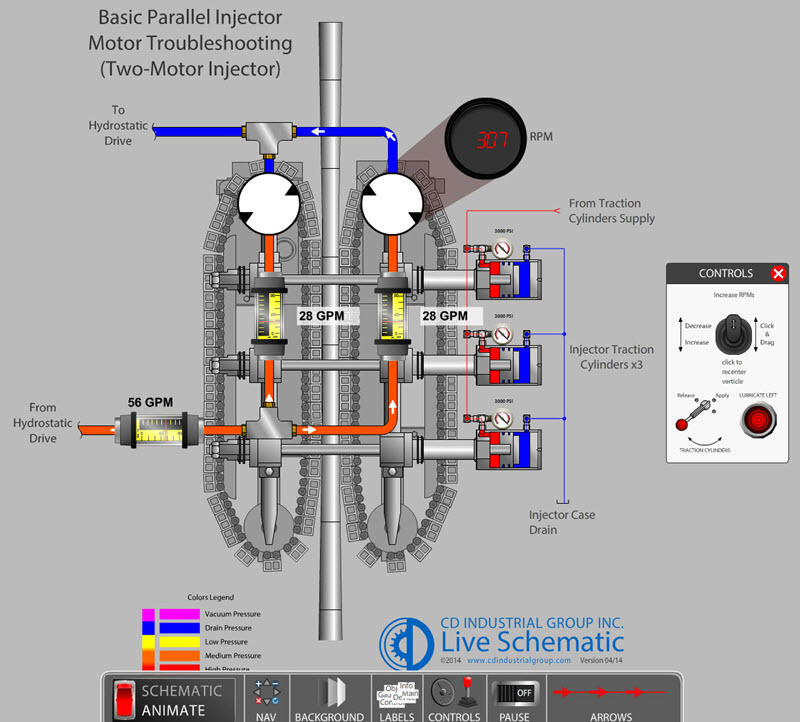

Injector Circuit - Traction

Objective: Explain traction apply/release, and pressure setting valves

Activity: Trace the traction circuit from control panel to injector"

Find out how the traction pressure is maintained if the hydraulic power unit fails!

The instructor made the course fun and helped everyone to understand why CT hydraulics circuits work the way they do.Devon M., Mountain Coil Tubing

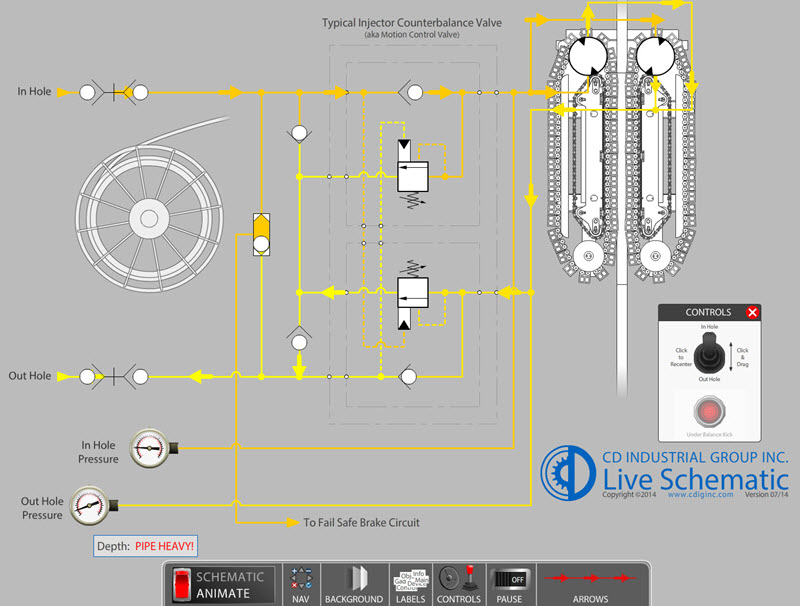

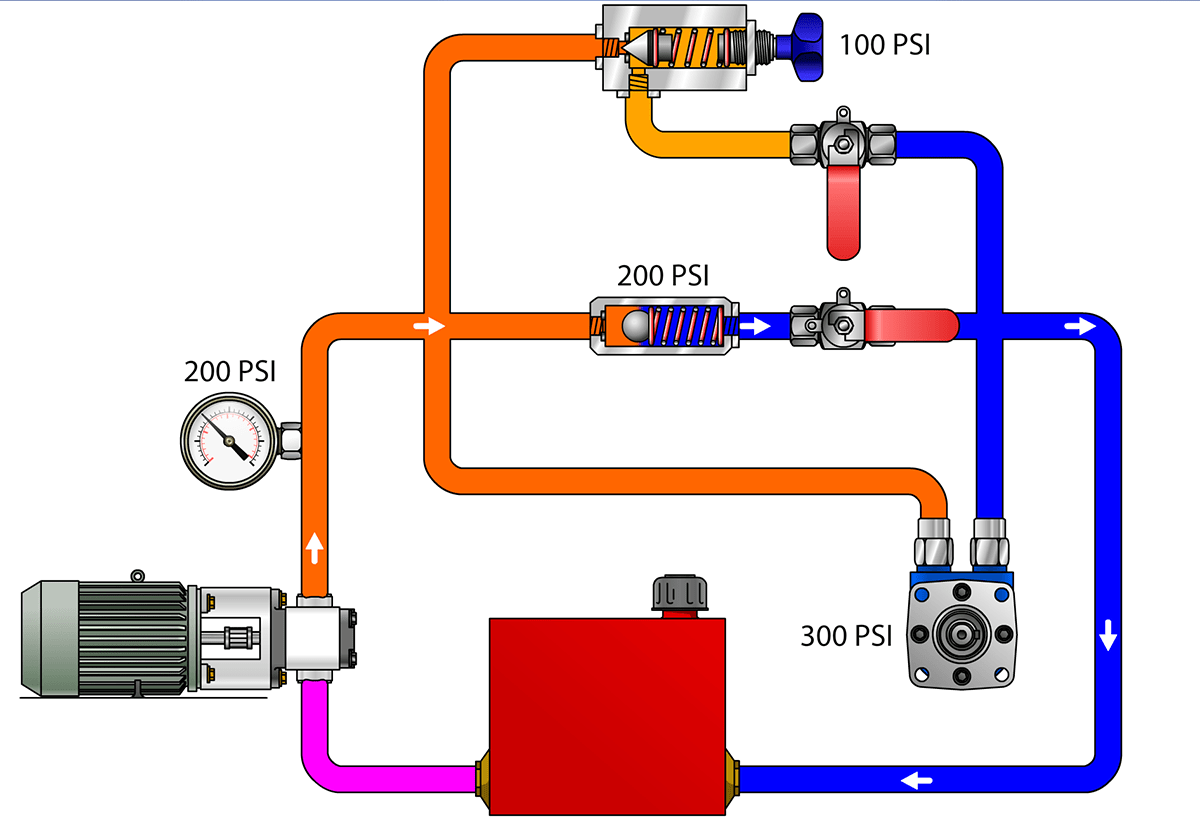

Theory

Objective: Explain the principals of hydraulics

Activity: Predict fluid behaviour in various systems

Learn about common fluidic misconceptions that affect troubleshooters

I was very impressed with the amount of information that I will be able to use when troubleshooting in the field.Kyle K., Trican

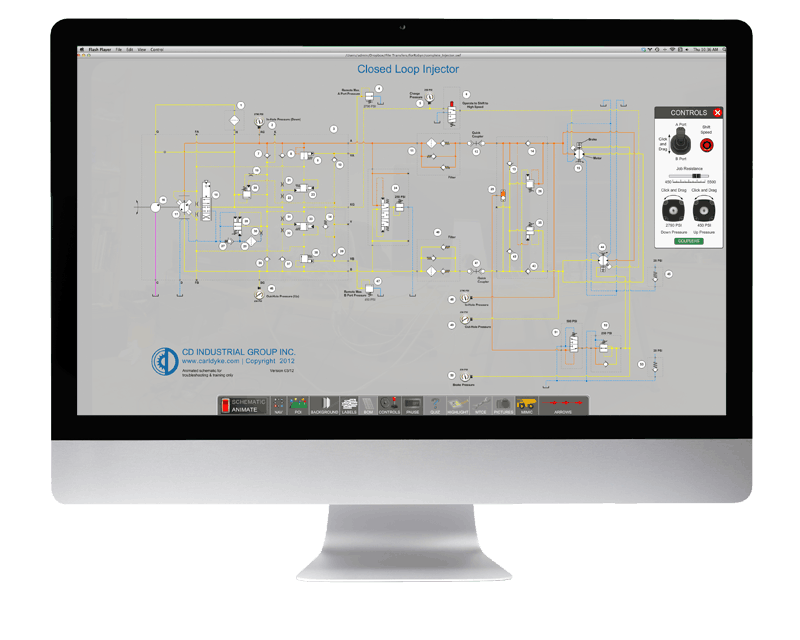

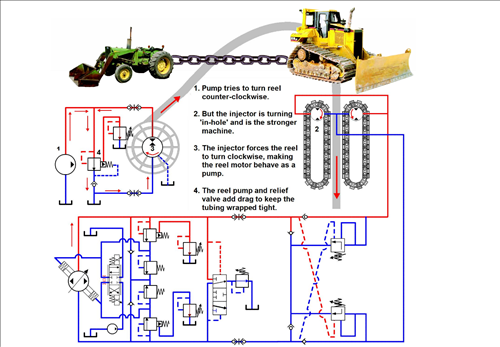

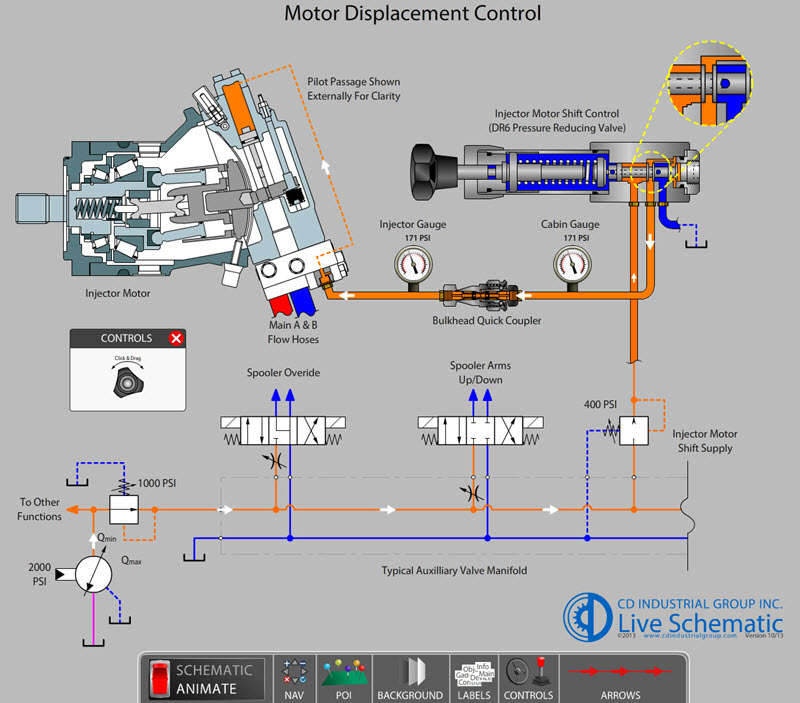

Closed Loop Injector Circuit

Objective: Explain the hydrostatic injector circuit and its functions

Activity: Predict test results for injector simulations

Interpret injector schematics and controls expertly

I enjoyed the working computer models that show the system paths and how the parts work. The course was 5 plus out of 5.Charlie A., Leader Energy

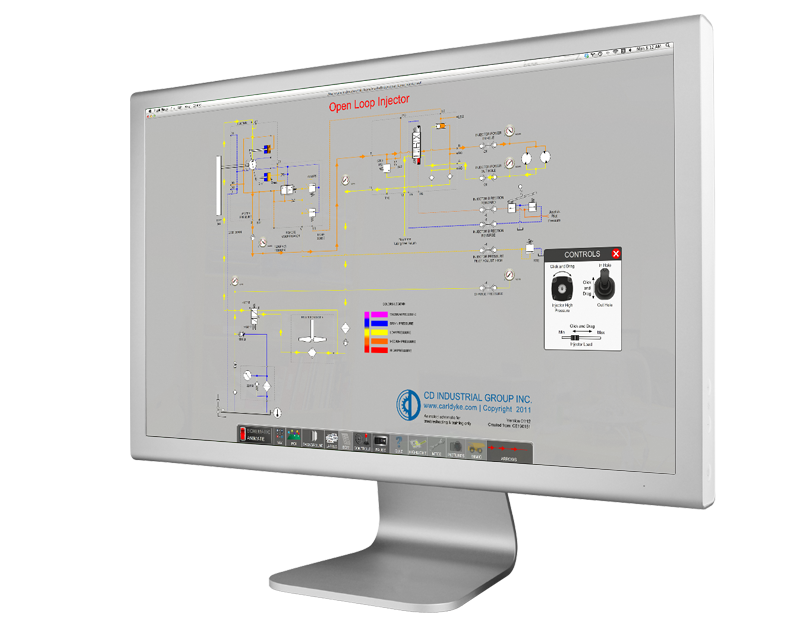

Open Loop Injector Circuit

Objective: Explain the circuitry used for load-sense injector drives

Activity: Predict test results for injector simulations

Interpret injector circuits that use the Parker Denison Premier P16 pump and similar

Awesome course content. Carl is a great teacher and the Live Schematics help a lot to understand internal workings.Tom E., FSC

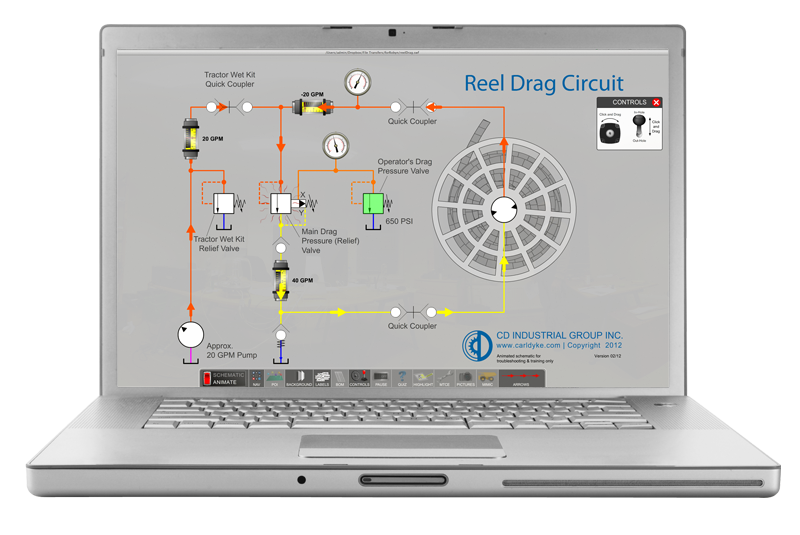

Reel Circuit

Objective: Explain reel drive and reel drag functions

Activity: Determine all flow path and directions through reel circuit

Diagnose and adjust reel drag problems

All CTU operators and mechanics need to come to this course to get at least some knowledge of hydraulic systems.Ubaldo D., Baker Hughes

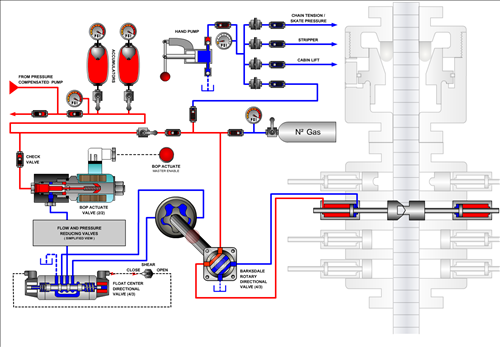

Auxiliary & Bop Circuits

Objective: Explain the auxiliary and BOP circuits and functions.

Activity: Describe BOP circuit tests

Know your BOP energy sources cold

The material was great. Hands-on work together with computer simulations from our exact equipment made the course valuable for our people.Eric P., Calfrac

Systems Design

Objective: Analyze complex circuit designs

Activity: Design circuits to solve hydraulics problems

Know your reel drag to injector motion control

This will be very valuable for field troubleshooting. The instructor used clear language and is passionate about hydraulics.Paul W., Canyon Technical

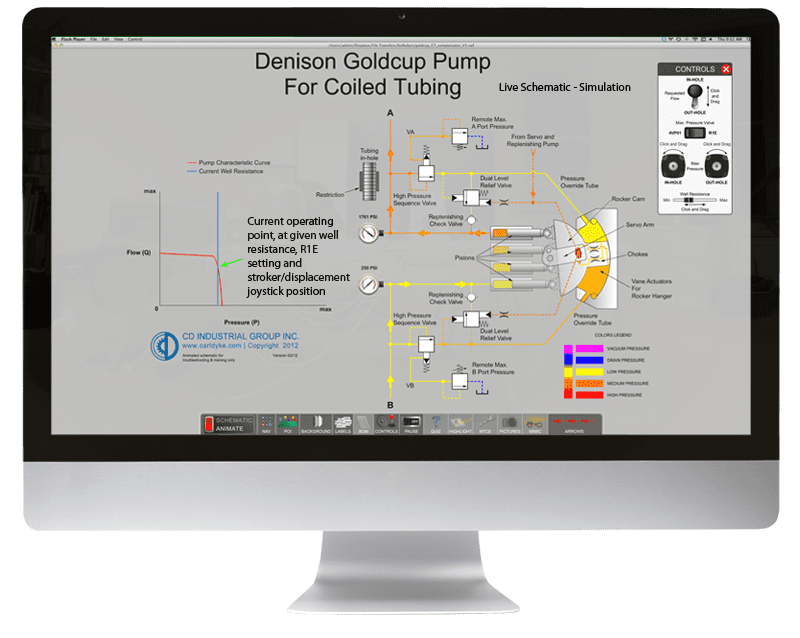

Hydraulic Pumps

Objective: Compare and explain the principles of various hydraulic pumps

Activity: Analysis of hydrostatic pump controls

Confidence with adjustments and settings on Parker Denison Premier and Goldcup P11 P14, Sauer Danfoss Series 90, Rexroth AA11 and A4V pumps and more

I learned about how to understand charge pressure and the true function of the R1E valve. The content was specific to my job and made me aware of what is going on with the hydraulics.Chilton M., Sanjel

Actuators

Objective: List procedures to diagnose common problems in actuators.

Activity: Motor and cylinder fault diagnosis

Poclain, Sauer Danfoss, Rexroth, Linde motors - porting, controls, and more

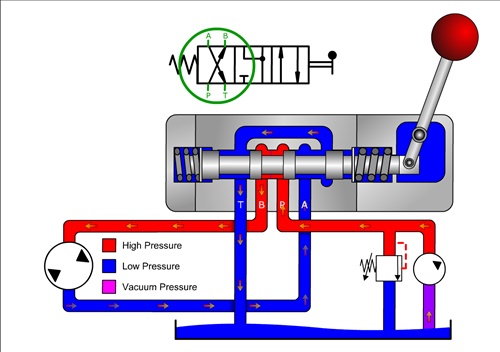

Valves

Objective: Identify valve designs and diagnose common problems.

Activity: Valve disassembly, inspection and reassembly

Hawe, Rexroth, Barksdale, Eaton - porting and configurations

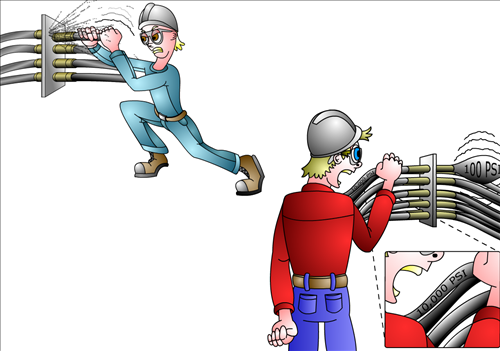

Safety

Objective: List common hydraulic hazards and safe procedures

Think before you act - even a few hundred PSI (or less) can injure or kill!

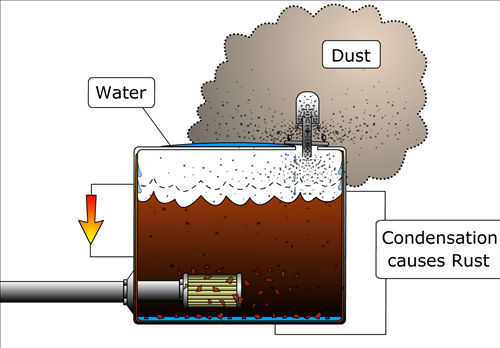

Preventative Maintenance

Objective: Describe preventative maintenance procedures

Activity: Identify maintenance tasks and frequencies for coiled tubing circuits

Avoid run-to-failure with good maintenance and planning

System Troubleshooting

Objective: List the steps in logical troubleshooting

Activity: Coiled tubing troubleshooting simulation exercises

Learn to troubleshoot methodically with the Ten Step Troubleshooting Process