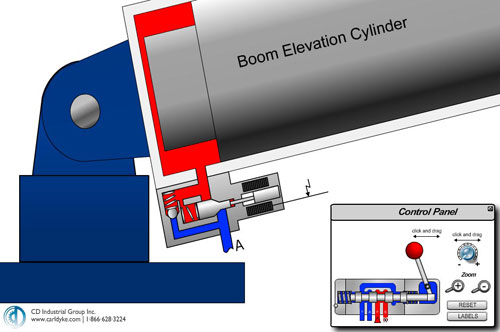

Day One: Operators & Mechanics

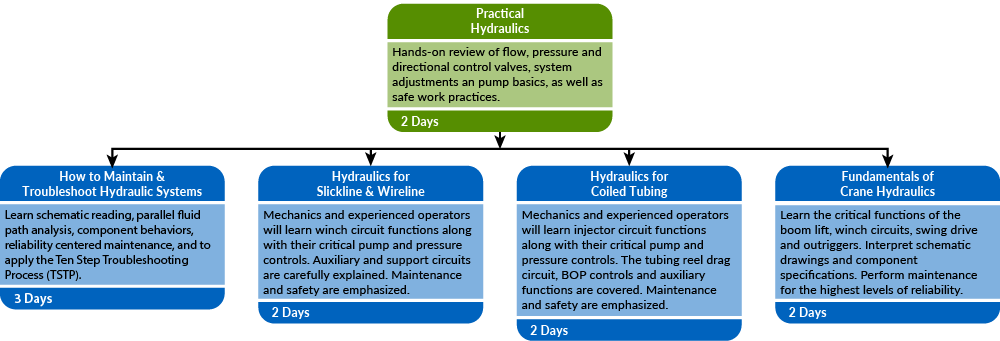

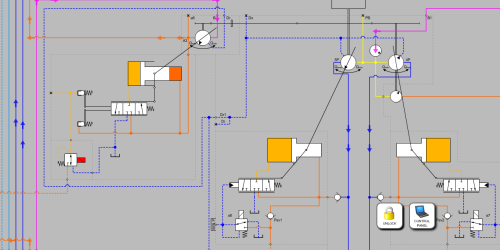

Winch Circuits

Objective: Explain the feature of typical crane winch circuits

Activity: Identify typical crane winch features on the schematic

Learn about features that prevent runaways and excessive line pulls

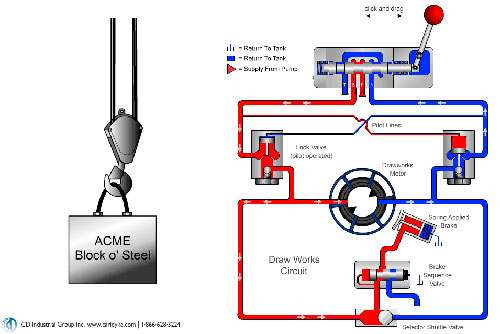

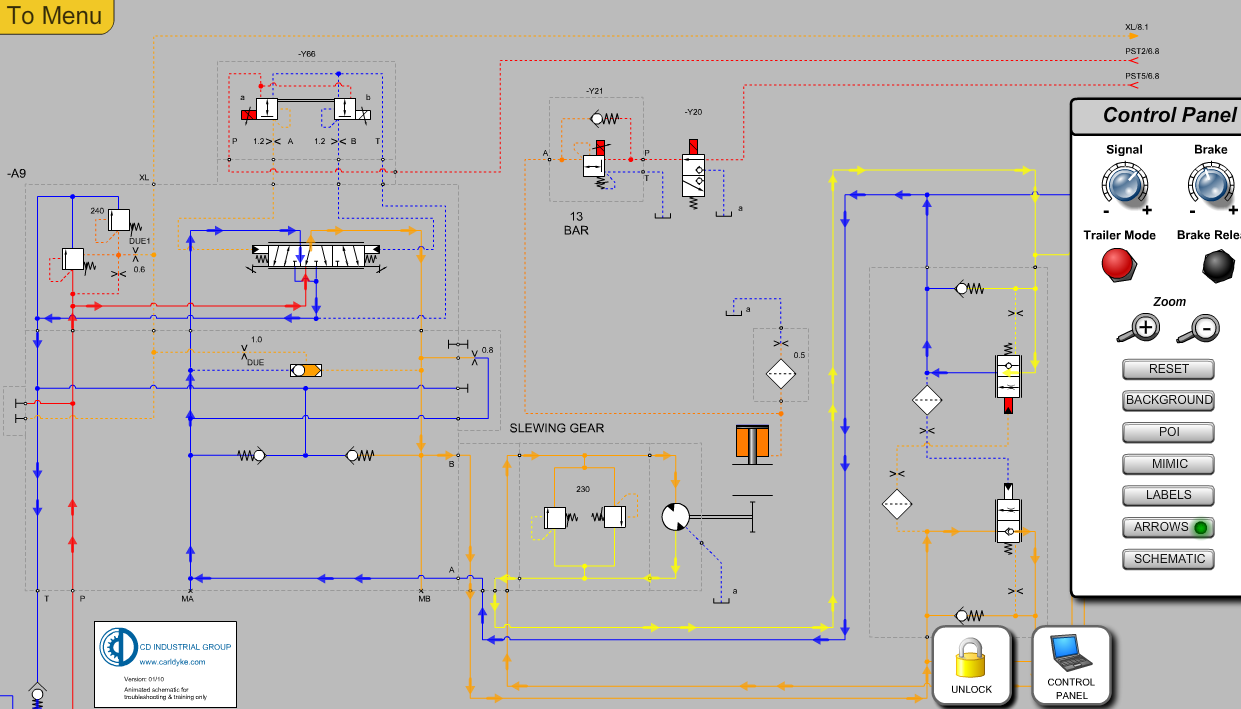

Slewing Circuit

Objective: Explain slewing circuit functions

Activity: Identify slewing components for normal function and boom dolly towing

Keep the slewing circuit in top condition

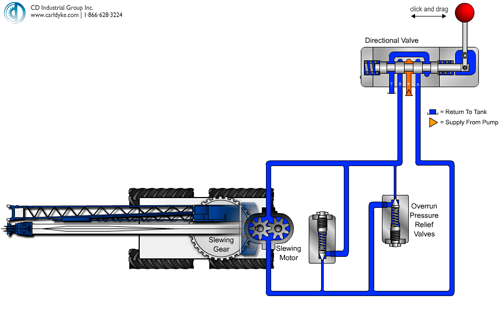

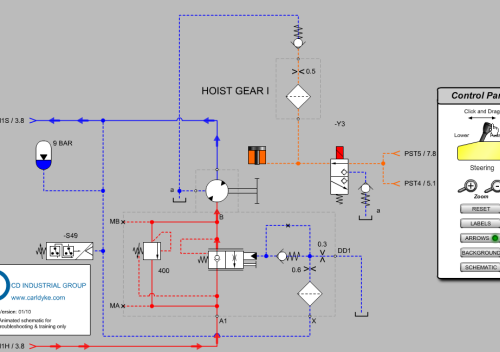

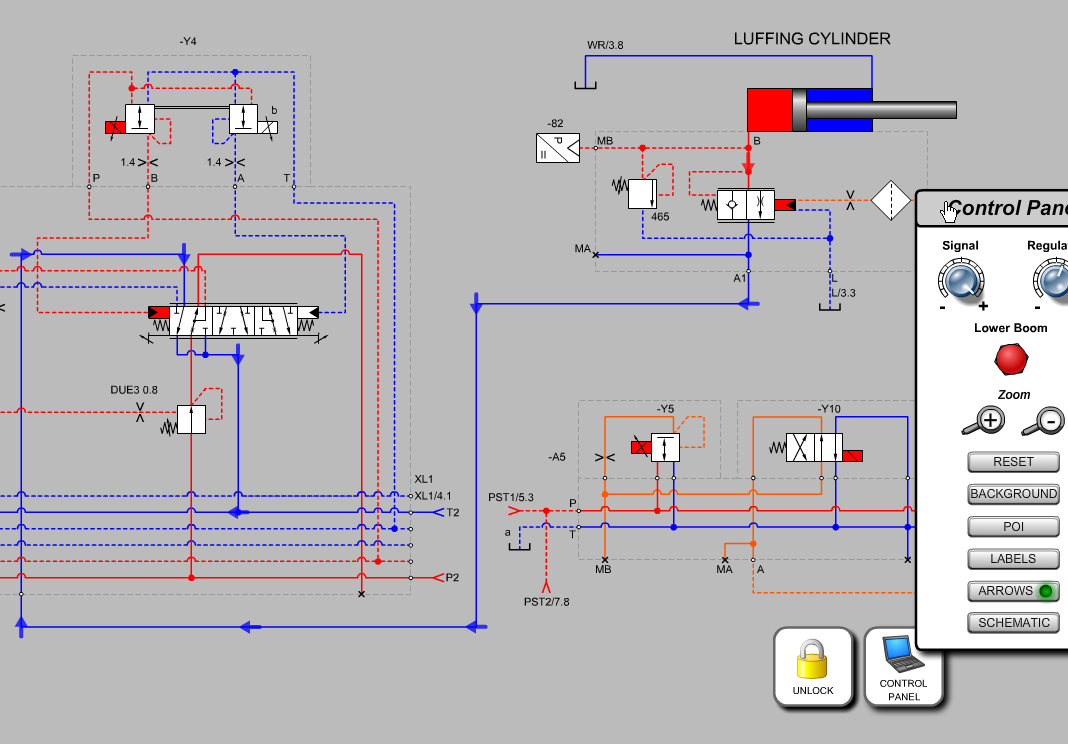

Boom Lift Circuit

Objective: Explain valving and safety features to lift and lock the boom

Activity: Trace out flow and pressure controls for the boom lift circuit

Find out how critical it is to keep the fluid clean

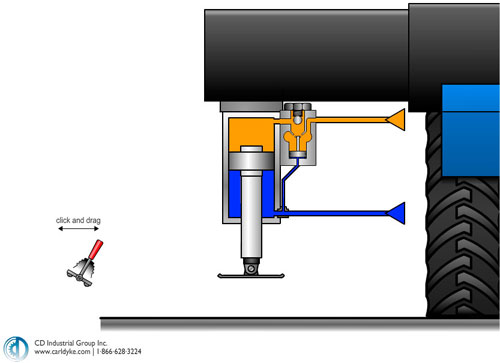

Outriggers

Objective: Explain outrigger circuit functions

Activity: Fully analyze the critical function of the lock valves

Find out how important clean oil is to keeping a crane upright

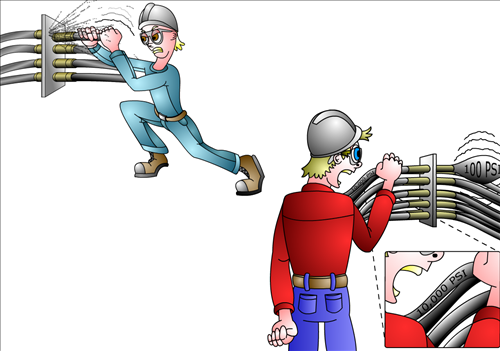

Safety

Objective: List common hydraulic hazards and safe procedures

Think before you act - a few hundred PSI (or less) can injure or kill!

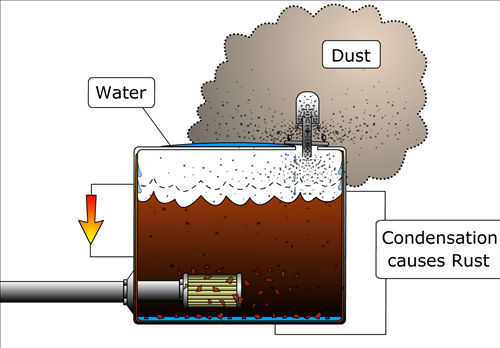

Preventative Maintenance

Objective: Describe preventative maintenance procedures

Activity: Identify maintenance tasks and frequencies for hydraulic cranes

Avoid "run-to-failure" with good maintenance and planning

Day Two: Mechanics

Theory and Design

Objective: Explain the principals of hydraulics that affect troubleshooting

Activity: Predict fluid behavior in various crane systems

Map out flow paths for faster troubleshooting

Hydraulic Pumps

Objective: Compare and explain the principles of various hydraulic pumps

Activity: Internal damage inspection and analysis of hydraulic fluid selections

Pump control mechanisms and load sensing features covered

Actuators

Objective: List procedures to diagnose common problems in actuators.

Activity: Motor and cylinder fault diagnosis

Find out why motor problems show up at slow speeds

Valves

Objective: Identify valve designs and diagnose common problems.

Activity: Valve disassembly, inspection and reassembly

Diagnose valve problems accurately - Is it mechanical or electrical?