PLCs & Electromechanical Motion Control Concepts

Learn to:

- Describe PLC systems and their basic functions

- Describe common hardware configurations

- Demonstrate the application of logic & numbering systems

- Demonstrate how to construct control programs

- Describe the types and operation of different I/O modules

- Isolate and solve system faults quickly, accurately and safely

- Explain the operation of positioning and pressure transducers

- Analyze Op Amps, PID's and conduct basic troubleshooting

- Explain proportional valve principles and make basic adjustments

- Identify servo valve designs and make basic adjustments

The objective of this course is to enable mechanical tradespersons to decide whether a machinery malfunction may have an electrical or control signal based fault. Participants will learn to use our methodical Ten Step Troubleshooting Process.

Upon completion of this course, participants will be able to explain the electrical controls, PLCs and sensor systems that interact with and control production machinery. The functions of electrical and electronic instruments that send positioning data and hydraulic pressure information to control cards and PLCs are covered. The electrical/electronic controls used with servo and proportional valves are also examined.

Electrical concepts will be made plain using comparisons to similar fluidic circuits and by using graphing instruments and computer simulations.

This material will be taught using an exposed low voltage (24 VDC and down) circuitry lab kit for each participant. The activities performed demystify the workings of controllers, sensors, and their related input and output processes.

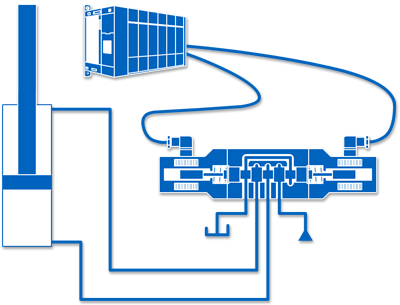

In addition a PLC simulation software package will be used that mimics RSLogix software while presenting a visual layout and animation of actual manufacturing and process machinery which trainees use to complete many of the hands-on exercises.

Topics

- Programmable Logic Control

- Plc Hardware

- Logic and Numbering Systems

- Plc Programming

- Input and Output Modules

- Plc Troubleshooting

- Cylinder Positioning and Pressure Transducers

- Valve Control Cards and Pid'S

- Proportional Valves

- Servo Valves

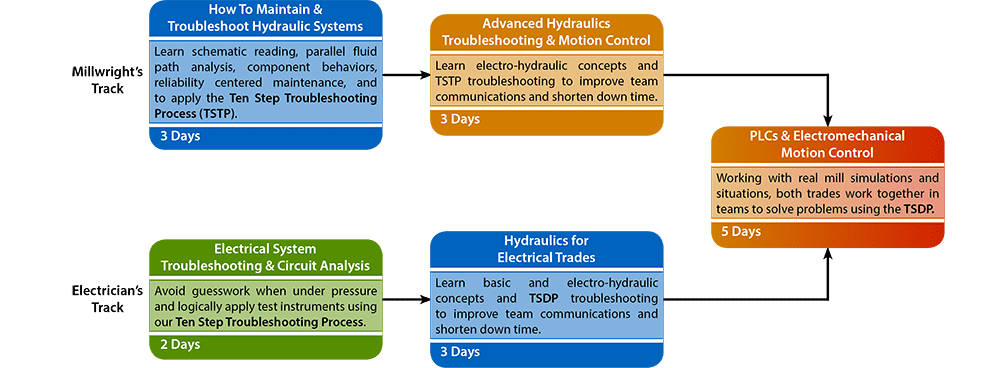

Where does this course fit in?

PLCs & Electromechanical Motion Control is the final course in our cross-trades training. After completing this course, you may want to learn more about PLCs with PLC Troubleshooting I, ControlLogix & RSLogix 5000 Basics, or Schenider/Modicon PLCs Level I, or you could continue your plant-based electrical training with Industrial Electronics Troubleshooting.