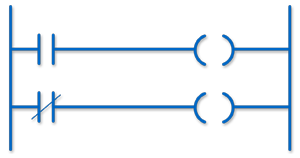

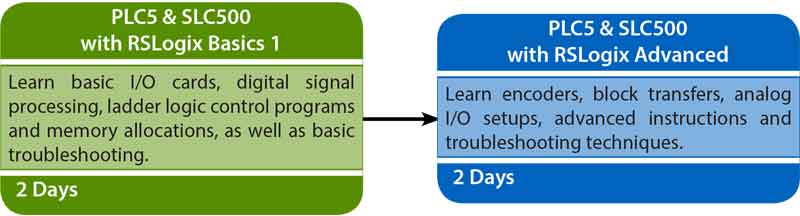

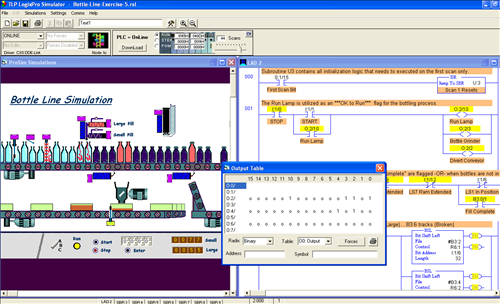

PLC Programming

Objective: Demonstrate how to construct/interpret control programs

Activity: Program solutions to real plant automation problems

All course participants receive their own licensed copy of this training software on CD-ROM

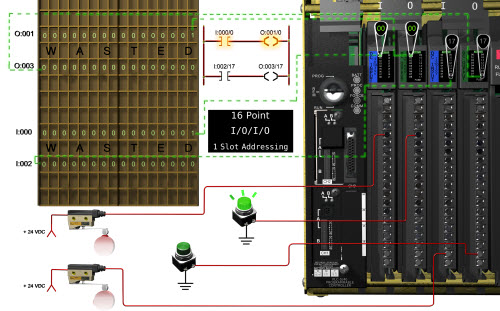

I/O and Slot Configuration

Objective: Correlate I/O points to memory addresses in PLC5 and SLC500

Activity: Rearrange cards in chassis and find bit access to the correct points/terminals in memory

Learn by play and experimentation in a safe environment

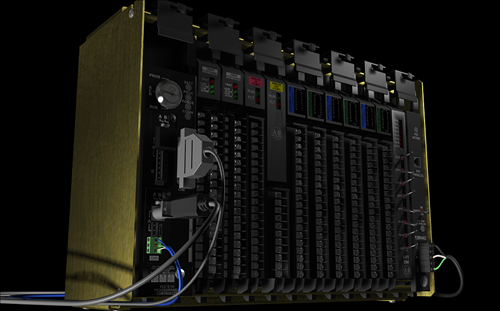

PLC Hardware

Objective: Describe common hardware configurations

Activity: Configure chassis, processors and I/O cards

Know your connectors, DIP switches, jumpers and fault LED's

Troubleshooting

Objective: Isolate and solve system faults quickly, accurately and safely

Activity: Diagnosing problems on simulator.

Use the PLC and its software as a troubleshooting tool

System Maintenance

Objective: Describe PLC maintenance tasks and techniques

Activity: Check backup batteries, cable connections, power supply, chassis condition/cleanliness.

Find out why some conscientious maintenance departments install a central vacuum close by to critical PLC cabinets