Hydraulic Pumps

Objective: Distinguish between gear, vane and piston pumps as used on gate systems

Activities: Conduct volumetric tests to trend pump wear issues

Avoid troubleshooting guesswork by knowing the condition & properties of the fluid source - the pump!

The instructor was very knowledgable and was able to shift to discuss location specific issues. Greg B., BC Hydro

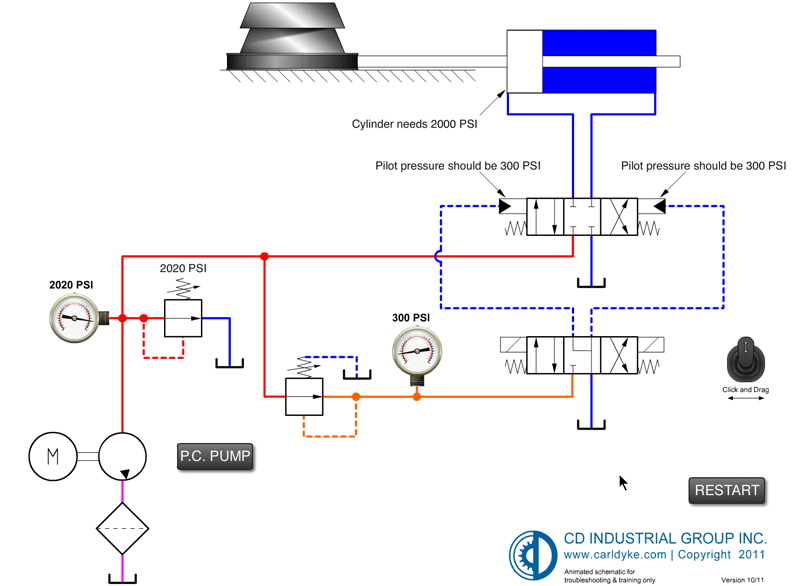

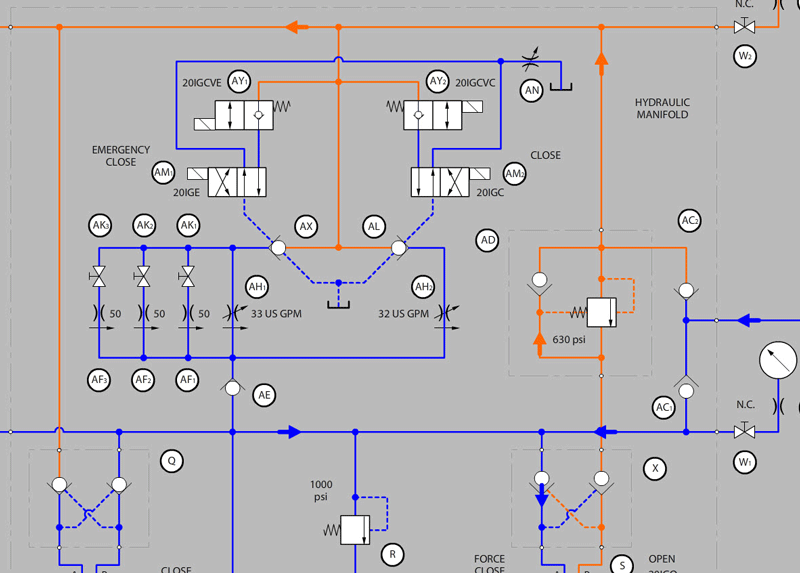

Directional Control Valves

Objective: Explain solenoid and pilot operated valve functions

Activities: Diagnose common directional valve problems

Know what makes the valve function and how to test it!

Pilot Operated Check Valves

Objective: Describe the function of pilot operated check valves

Activities: Test for a damage check valve seat

Know pilot supply and drain line issues cold!

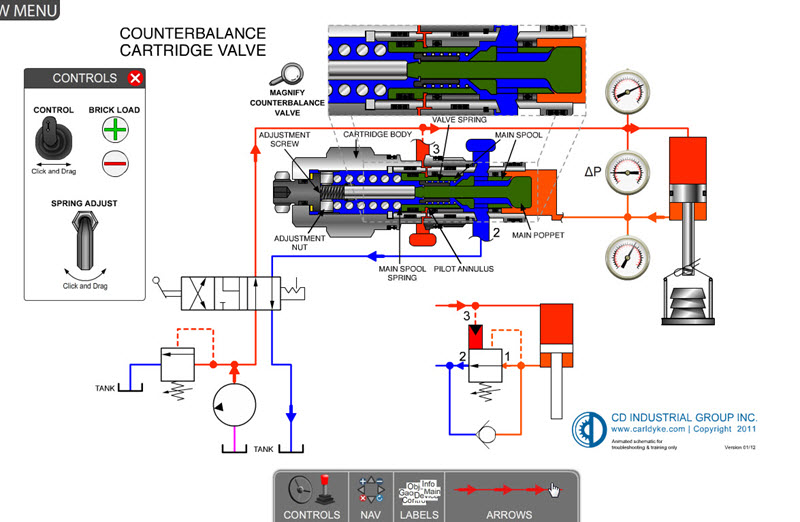

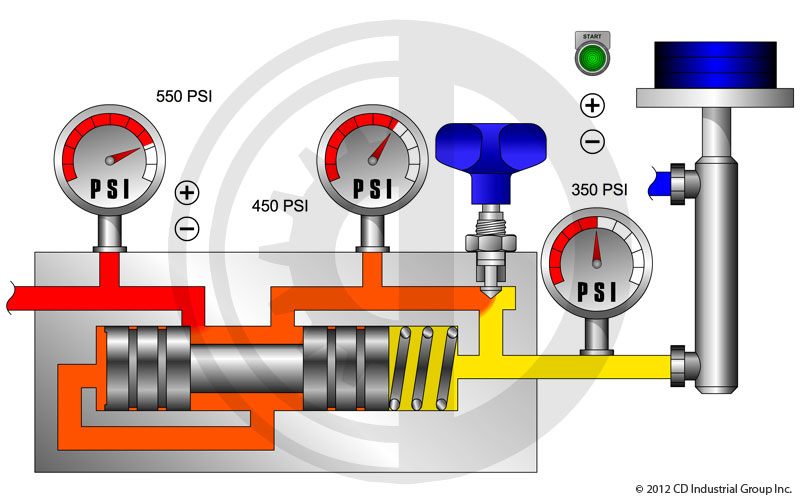

Pressure Control Valves

Objective: Differentiate between relief, pressure reducing and counterbalance valves

Activities: Correctly adjust and diagnose pressure valves

Recognize pressure valve types by symbol & their location within the circuit

Flow Control Valves

Objective: Distinguish between basic and pressure compensated flow controls

Activities: Diagnose and test for a stuck pressure compensator spool

Hydraulic Cylinders

Objective: List procedures to diagnose common problems in cylinders and motors

Activities: Work with an internal cylinder leakage simulation and with our cylinder bypass panel

Avoid myths and accurately diagnose gate cylinder drift!

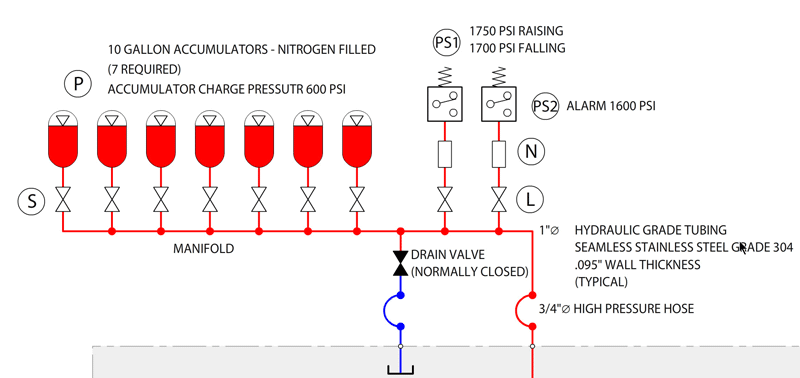

Accumulator Banks

Objective: Describe characteristics of a properly functioning accumulator bank

Activities: Precharge an accumulator using correct, safe procedures

Determine basic accumulator condition via external observations