Why Align?

Objective: List consequences from failure to align

Activity: Identify machine components that have failed due to misalignment

Make a notable contribution to coupling, bearing and seal life! Minimize vibration and energy consumption!

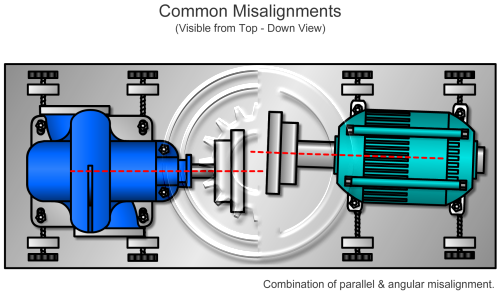

Alignment Theory

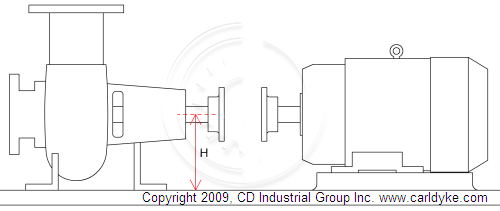

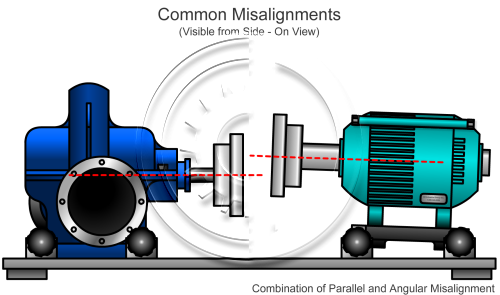

Objective: Describe the common types of shaft misalignment

Activity: Identify parallel offset and angularity

Use simple alignment math and graphs! Take thermal offset into account!

Preparing For Alignment

Objective: List steps to prepare for a shaft re-alignment

Activity: Use feeler gauges and dial indicators to test for irregular machine status

Review recent maintenance records for valuable clues and begin safe lockout procedures

Measuring Soft Foot

Objective: Detect and correct soft foot conditions

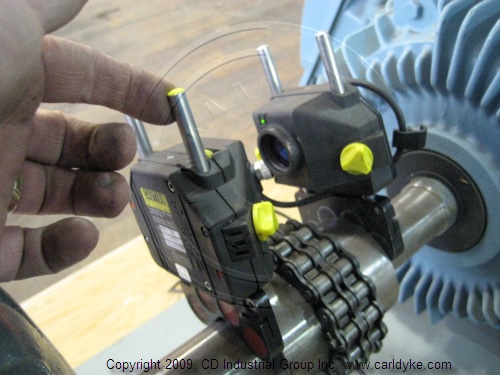

Activity: Use magnetic base with dial indicator

Learn when and when not to correct foot

Detecting Runout

Objective: Detect shaft and coupling runout conditions

Activity: Use magnetic base with dial indicator

Can you proceed with alignment when there is shaft/coupling runout

Straight Edge Techniques

Objective: Use basic tools to achieve rough alignment

Activity: Complete a hands-on rough alignment using straight edge techniques

Put feeler gauges, vernier callipers and straight edges to good use to achieve initial roughed-in shimming and horizontal alignment

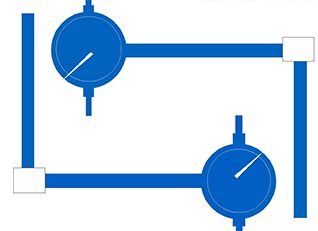

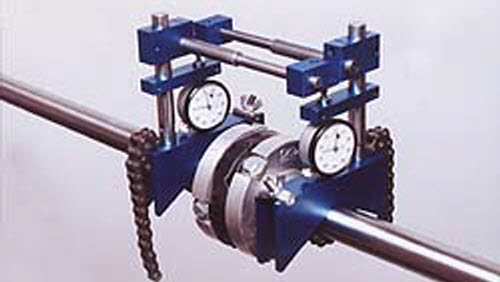

Reverse Dial Techniques

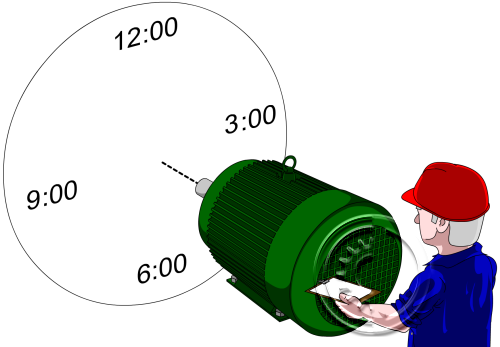

Objective: Demonstrate correct reverse dial alignment routines

Activity: Complete two computer simulated and two hands-on alignment jobs using reverse dial techniques

Setup brackets and indicators, correct for bar sag, take accurate measurements and make vertical and horizontal moves

Horizontal and Vertical Moves

Objective: Shim and make horizontal moves

Activity: Use shims and dials for both horizontal and vertical moves

Do you shim for vertical moves first, or make horizontal moves first?

Intro to Alternative Techniques

Objective: List advantages of rim and face dialling and laser alignment